Elasticity of Materials – Basic Principles:

In the science of physics, elasticity is the ability of a deformable body (e.g., steel, aluminum, wood, etc.) to resist a distorting effect and to return to its original size and shape when that influence or force is removed. Solid bodies will deform when satisfying forces are applied to them.

The elasticity concept of solid materials is the deformation with the external force application and recovery to its original shape after the forces removed. Parameters are: stress (force per area) and strain (deformation per unit length).

Elasticity of Materials – Basic Principles: Young’s Modulus Explained

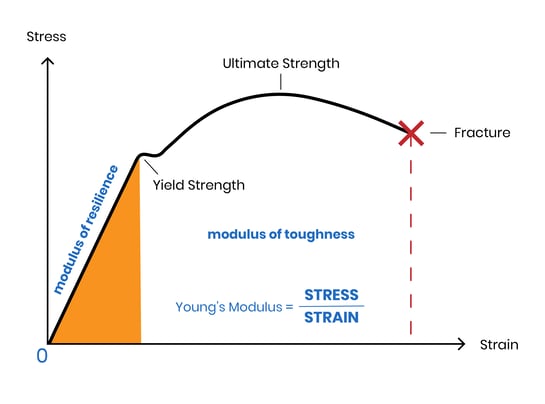

Young’s Modulus/Initial Modulus is the initial part of a stress/strain curve and describes the ability to resist elastic deformation under load. It describes a material’s propensity to retain its shape, even when it is being stretched, pulled, twisted, or compressed.

So, Young’s Modulus=Stress/Strain.

When a material has a high modulus, even under extreme strain the material resists the initial force and recovers well. For a lower modulus material, strain stresses it and creates the risk of breaking, which is illustrated in the stress-strain curve below.

Terms Related to Young’s Modulus:

Stress: A tension created by the application of a lengthwise load.

Strain: Change in length from stress acting parallel to the longitudinal axis of the material.

Creep: This is time-related, non-recoverable damage due to sustained stress.

Fatigue: Fatigue is when a material weakens due to repeatedly applied loads.

Stiffness: A stiff material has a high Young’s Modulus.

Deformation: Also known as plastic deformation, this is the warping that occurs under stress.

Elastic limit: This is the limit beyond which the material is deformed.

Yielding: Just beyond the elastic limit is permanent deformation known as yielding.

Strain Hardening: Beyond yielding, this is a maximum or ultimate stress.

Fracture: Beyond ultimate stress is the fracture, or breaking, point.

Elasticity of Materials – Basic Principles: High Modulus Materials

A high modulus is preferable in a wide variety of industrial and commercial materials for purposes of resilience, safety, and reliability. Because of the more desirable tensile characteristics for specific applications, high modulus material variants are often more expensive than standard modulus materials.

References:

1. Todhunter I. A history of the theory of elasticity and of strength of the materials from Galilei to the present time, Vol. II. Saint-Venant to Lord Kelvin. King’s College, Cambridge: Pearson; 1893.

2. Timoshenko SP, Goodier JN. Theory of Elasticity. 3rd ed. New York: McGraw-Hill; 1970.

Santiago Martinez – www.windydaysproducts.com

Hooke `s elasticity law rules